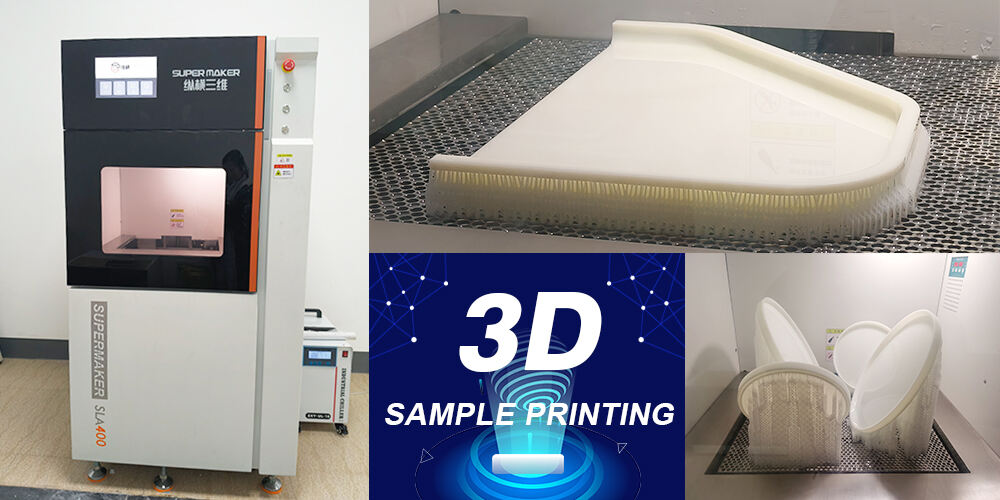

خذ مثلاً شهر أغسطس من هذا العام، فقد تم مؤخراً تقديم نموذج طابعة ثلاثية الأبعاد. ويمكن إدراك التداعيات الكبيرة لهذا الأمر من قبل مصنعنا وبشكل تدريجي منذ أن أصبحت الممارسات البديلة شبه مكلفة للغاية.

في الأوقات السابقة، كان إعداد العينات بشكل تقليدي يستهلك ساعات عمل ثمينة. ولكن في عصر طابعات ثلاثية الأبعاد، يمكن تسريع العملية إلى حدٍ ما. تُقدّر الإبداعات والتطورات التكنولوجية باعتبارها مؤشرات صغيرة على التقدير. يمكن للمهندسين إرسال تصاميمهم الرقمية مباشرةً إلى طابعة ثلاثية الأبعاد.

تستخدم الطابعة بيانات التصميم لبناء كل طبقة بسرعة، ويمكنها تحقيق أدق التفاصيل في التصميم، مثل الموجات المعقدة والقوام الدقيق أو الأشكال الدقيقة.

من الواضح أنه عندما ترسخ الطابعات ثلاثية الأبعاد في السوق، فإن إنتاجية المصنع سترتفع قفزة كبرى، مما سينعكس أخيراً على التكاليف بشكل خفضٍ لها.